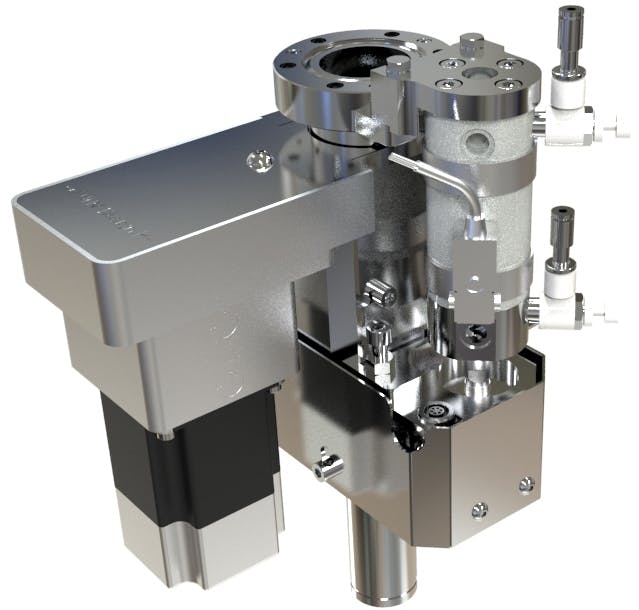

Hollow rotary drive with integrated lift & lower

Compact and Efficient Solution for Precision Applications

The Magilift provides magnetically-coupled rotation and axial motion in a single, compact device, making it a versatile tool for precision tasks. Designed for applications such as substrate handling, it combines both rotary and lift/lower functions, allowing for seamless sample transfer and movement. With its hollow drive technology, essential services can be passed through to a substrate heating module, ensuring smooth operation and convenience in vacuum environments.

Key Specifications

- Rotational speed: Up to 60 RPM with 25mm axial motion.

- 27.8mm hollow bore to enable the passage of services like cooling or heating elements.

- 140N linear coupling force and 9 Nm rotary torque for high power in a compact device.

- Bakeable to 250°C without the need to remove external magnets, maintaining operational efficiency.

- Maximum axial load: 20N (4.5 lbf ft) for robust handling in demanding applications.

- Options for both motorisation and pneumatic actuation provide flexibility in control.

- Custom shaft designs available for unique application requirements.

Advanced Hollow Rotary Drive Technology:

The Magilift’s magnetically-coupled design eliminates the need for traditional components like bellows or seals, reducing the risk of leaks and wear. This ensures long-term reliability and minimises maintenance in UHV (ultra-high vacuum) systems. Its combination of rotational and axial movement makes it ideal for complex tasks such as sample positioning, where precision and uniformity are critical.

MLR35 – Magnetic Rotary and Linear Motion Manipulator

The MLR35 model expands upon the Magilift capabilities by enabling rotary and axial motion in a central hollow shaft, making it perfect for substrate rotation in vacuum chambers. With a rotation speed of 60 RPM and 25mm of axial movement, it ensures precise control in UHV environments, enhancing operations like substrate uniformity in front of heaters or deposition sources.

- Magnetically-coupled mechanism: This system avoids the use of sliding seals and bellows, ensuring durability and reducing contamination risks.

- High torque and axial thrust: The optimised magnetic coupling ensures powerful, precise movement, critical for scientific applications and light industrial use.

Applications:

- Substrate handling in vacuum chambers for research and semiconductor manufacturing.

- High-precision sample transfer in laboratory automation and scientific instrumentation.

- Axial and rotary motion control in UHV systems for surface analysis and material science.

Custom Solutions Available

Our engineering team can provide custom shafts and configurations to match the specific needs of your project. Whether you are working in scientific research, semiconductor production, or vacuum system integration, the Magilift offers an unparalleled combination of precision and reliability.

Product configuration tool

If you would like to discuss your project with our engineering team, please contact us.