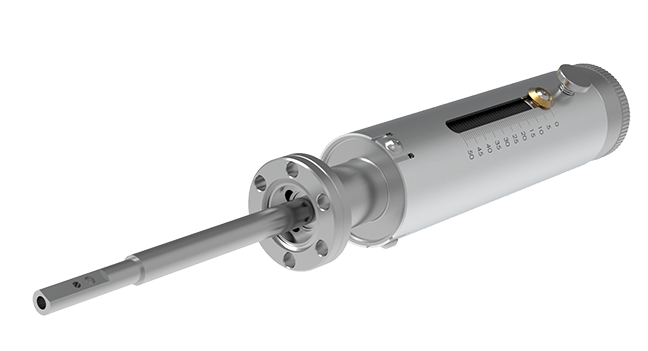

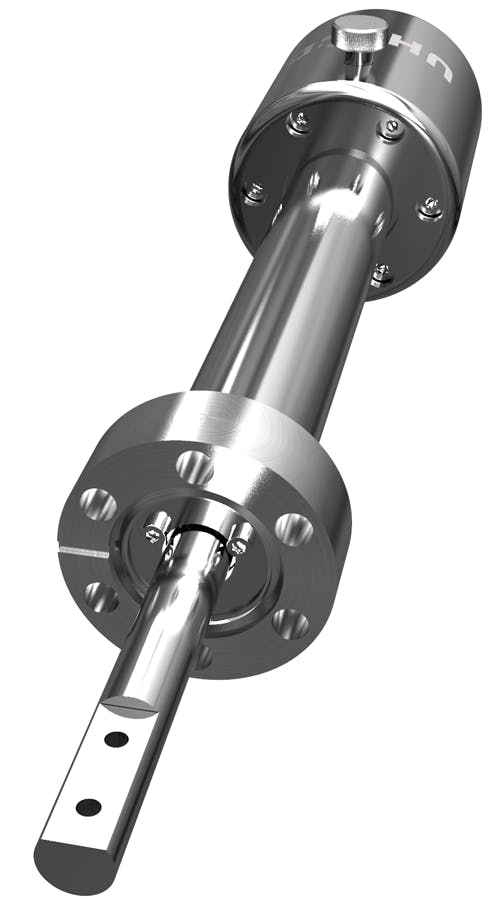

Linear Actuators: Bellows-Sealed & Magnetically Coupled Solutions

UHV Design's bellows-sealed and magnetically coupled linear actuators are expertly engineered to address a wide range of industrial and scientific applications. From precision tasks like beamline filters and wire scanners to complex deposition stages and production environments, our actuators are built for superior performance and reliability.

Whether you're operating in a research lab or a high-demand production facility, our linear actuators provide the precision and durability needed for optimal operation in ultra-high vacuum (UHV) environments.

Key Features

- Bellows-Sealed and Magnetically Coupled Options: Ensuring operational integrity and cleanliness in UHV environments.

- Field-Proven Reliability: Decades of usage in critical applications across multiple industries.

- Comprehensive Customisation Options: including custom stroke lengths to custom end effectors.

- True UHV Compatibility: Built to withstand demanding vacuum conditions while ensuring high accuracy and performance.

Product Customisation

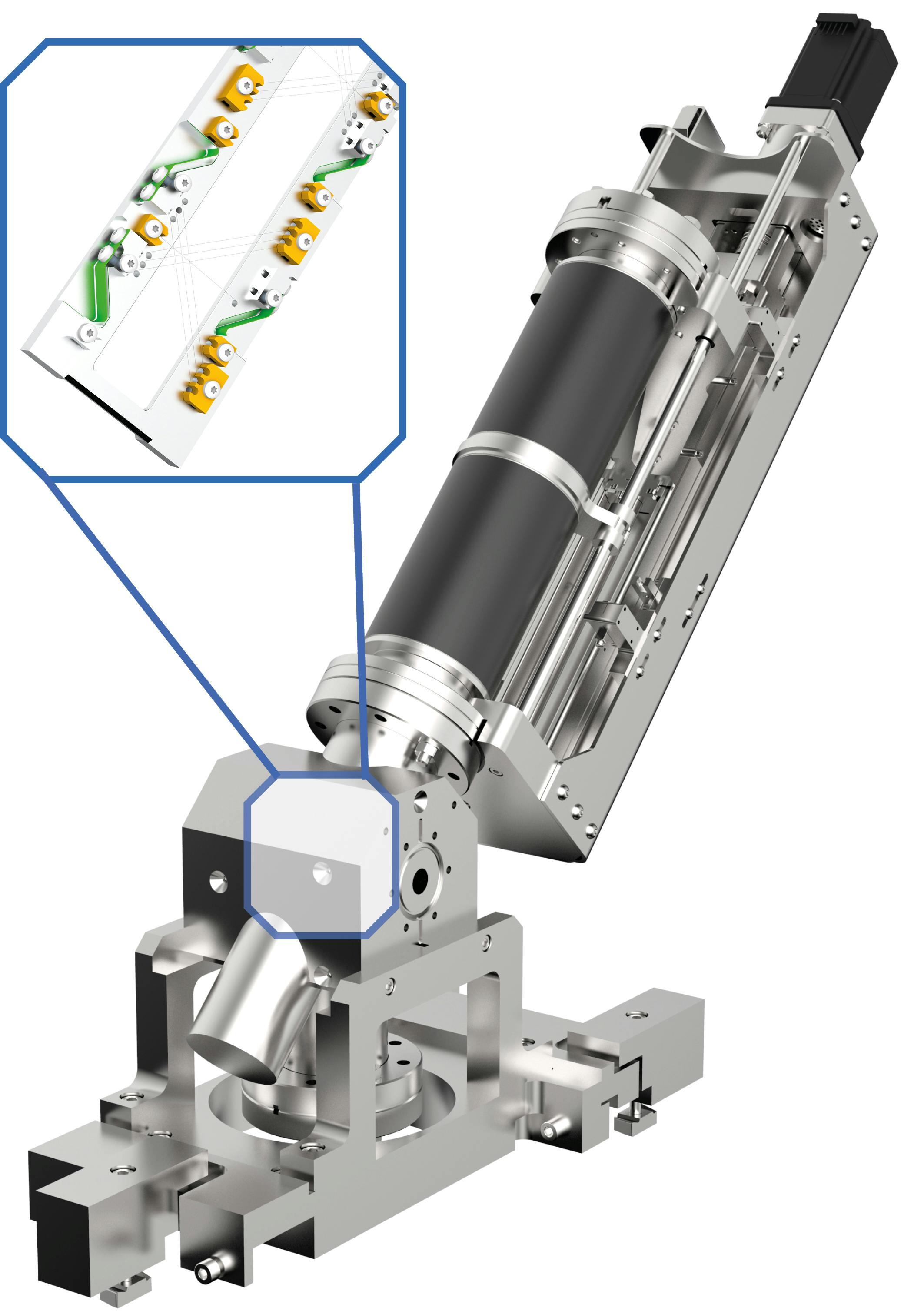

Our linear actuators are highly customisable, allowing you to tailor them to your specific needs. Options include:

- Motorisation: For precise electronic control and automation.

- Pneumatic Actuation: Ideal for fast and reliable linear motion without compromising vacuum integrity.

- Custom Shafts: Available for unique application requirements.

- Encoder Choices: For high-resolution feedback and position accuracy.

- High-Speed Options: Achieve speeds of up to 100mm/s using a ball screw mechanism.

These customisation options make our linear actuators the preferred choice for sputter sources, deposition stages, and production style applications.

Applications

- Beamline Filters: Precise control for scientific experiments.

- Wire Scanners: High-speed and accurate motion solutions for scanning applications.

- Sputter Sources: Enhancing precision in material deposition.

- Deposition Stages: Smooth, reliable performance in thin-film and vacuum deposition environments.

- Production Applications: Robust, reliable actuators that meet the needs of modern industrial automation.

Why Choose UHV Design Linear Actuators?

Our linear actuators stand out for their flexibility, performance, and reliability. Whether it's high-speed motion or custom actuation, we can meet your exact requirements. Built with a focus on industrial automation and precision, our actuators excel in high vacuum environments, providing reliable performance across industries.

To learn more, view our full product range or contact our team for customised solutions.

Linear Actuators: Bellows-Sealed & Magnetically Coupled Solutions series and product options

If you would like to discuss your project with our engineering team, please contact us.