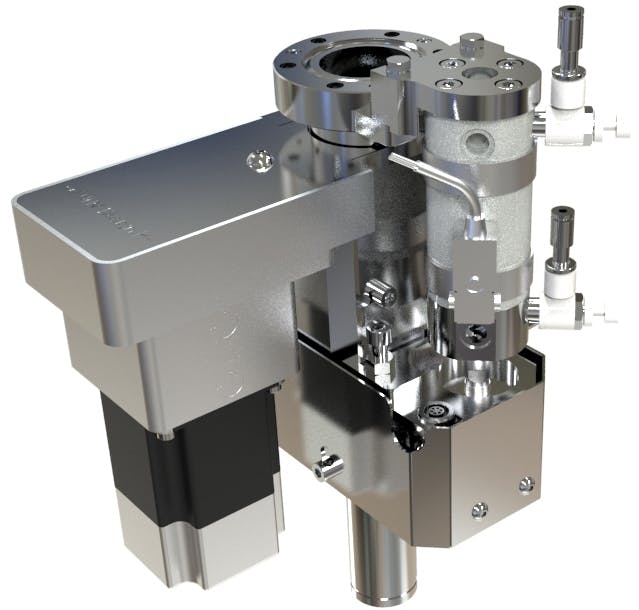

Rotary feedthroughs

Our innovative and production-proven MagiDrive range.

This range of vacuum rotary feedthroughs enables rotation to be transferred into a vacuum system via a stiff high-flux magnetic coupling. With no bellows, fluids or dynamic seals, the MagiDrive range offers reliable and leak-tight UHV operation.

Key Features

- Magnetically-coupled, fail-safe design

- Single-piece vacuum enclosure ensures leak-free performance

- Magnetic shielding permits use in magnetically-sensitive environments

- No bellows, organics or sliding seals

- Bakeable to 250ºC (including magnets)

- High torque-to-size ratio

- No backlash under low load and acceleration

- Hollow variants allow stacking of concentric drives

Rotary feedthroughs series and product options

If you would like to discuss your project with our engineering team, please contact us.