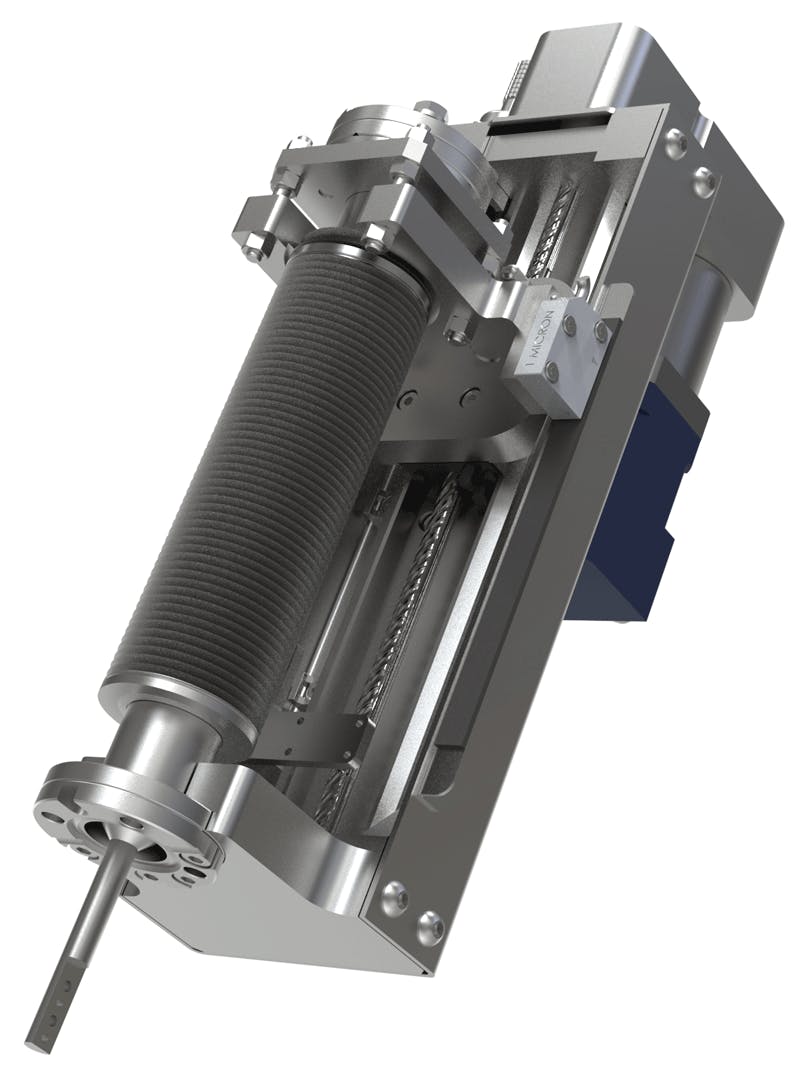

Standard linear shift

Our LSM & HLSM Series

Bellows sealed Linear Shift Mechanisms (LSMs) provide linear motion along the port axis (Z). Typical applications include positioning beamline filters and adjusting sputter sources. They can also be used for everything from deposition stages right through to production style applications.

UHV Design has the largest range of LSMs in the world. This ranges from CF35 to CF150 flanges, up to 1m stroke and tilt & X alignment versions with manual, pneumatic and motorisation options. What’s more, these are all available with a range of position encoders.

Our LSM & HLSM Series

UHV Design’s CLSM Series

UHV Design’s LSMT Series

UHV Design's LSMX Series

UHV Design’s HLSML Series

Our PLSM Series

Linear shift customisation options include different methods of actuation, addition of encoders and other custom features to suit your application.

If you would like to discuss your project with our engineering team, please contact us.